Automated Ball Indentation (ABI)®

Technology

What is

Automated Ball Indentation (ABI)® Technology?

ABI® is a nondestructive mechanical testing technique for determining tensile and fracture toughness properties. It is based on progressive indentation with intermediate partial unloadings until the maximum depth (maximum strain) is reached, and then the indenter is fully unloaded. The ABI® test is a macroscopic (bulk) technique that measures the properties on a small volume of material.

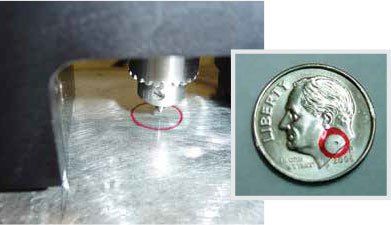

The ABI® technique is ideal for testing in-service components where cutting samples is either too costly or impractical – such as pipelines. The spherical indentations produced on the pipe surface are shallow, smooth depressions with no sharp edges or stress concentration sites.

How ABI® Technology Works

- Ball indentations are shallow, with smooth edges and produce compressive stresses in the material that retard crack initiation

- The remaining ABI® depression is similar to one from shot-peening or sand blasting.

Applications for

ABI® Technology

- 2” outer diameter (OD) and larger pipes

- 7” long sections and larger

- Compression station piping

- Ends/elbows

- Fittings

What ABI® Technology Measures

The Automated Ball Indentation® technology provides in-situ testing on in-service components to measure key mechanical properties including yield strength, flow properties, strain hardening parameters, and fracture toughness of ferritic steels.

Advantages of ABI® Technology

Testing can be performed directly on the component, thus eliminating the need to destroy the component and cut samples. We can design and manufacture custom fixtures if necessary, and we have a local machine shop to keep costs low.

Work with ABI® Integrity Services

ABI® Integrity Services owns exclusive rights and access to ABI® technology for us to perform professional test and analysis on steel infrastructures. Learn more about how ABI® Integrity Services technology can help with your specific project needs, feel free to

contact us today.